Stearic Acid Cosmetic Grade

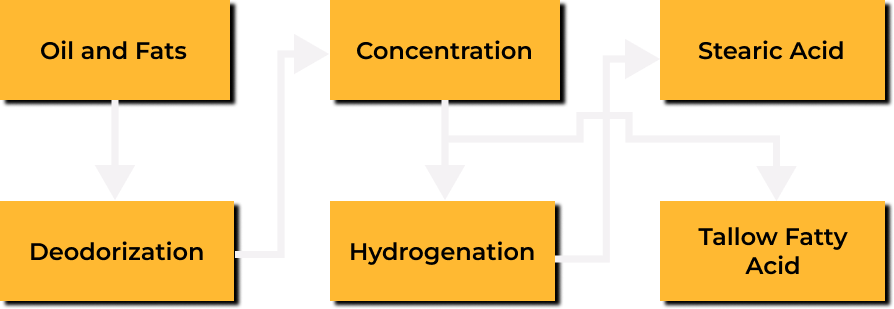

Manufacturing Process

The production of commercially available triple-based stearic acid is carried out by a compression process. Fats and oils are hydrolyzed at high pressure and high temperature to form chains of fatty acids and glycerol. The product is purified by washing and distillation before being compressed to remove oleic acid. Compression is done in several stages, each with different purity. The triple press process provides the highest purity stearic acid compared to the double and single press processes.

Applications

1. Emulsifying agent

Stearic acid emulsifying properties reduce water surface tension to prevent separation between oil and water. The compound helps to maintain the smooth and creamy texture of personal care products.

2. Cleansing

Stearic acid is considered as a reliable cleanser. The compound binds oil and water together that usually separates. Facial cleansers utilize stearic acid to eliminate remaining dirt and oil on the surface of the skin.

3. Masking

Stearic acid has a masking properties that covers unpleasant odour in cosmetic products by suppressing the source compound.

4. Refatting

Stearic acid provides the oil needed on the surface of the skin to form a layer of lipids. The layer inhibits water evaporation and helps to moisturize the skin.